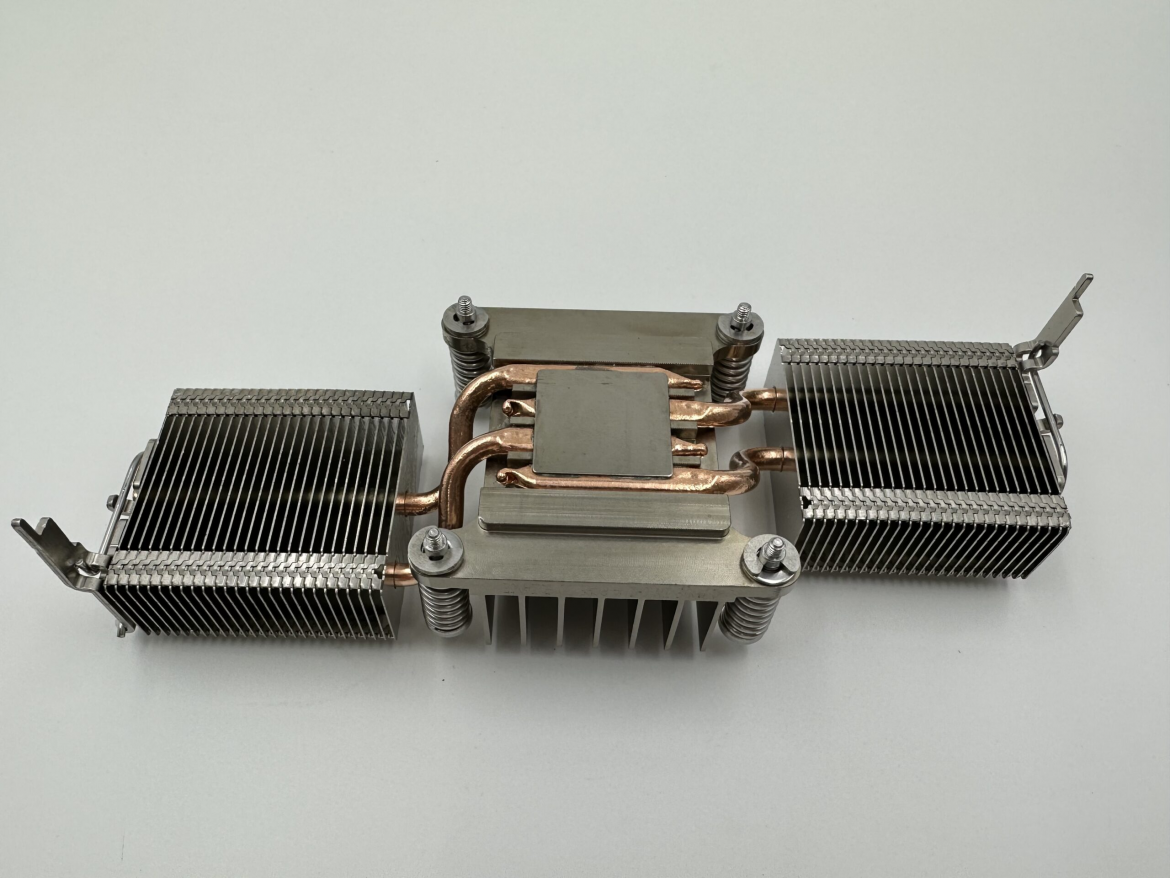

A heat pipe heat sink is commonly used in applications where engineers need stable and efficient temperature control, and its effectiveness depends greatly on how the internal components work together. When discussing these systems, many industry professionals look at both the material selection and internal structure to understand why they perform reliably. A heat pipe heatsink generally contains sealed heat pipes, a conductive base plate, and an array of fins that together form an integrated thermal path. As a manufacturer, Dingmetal is often referenced by engineers because they provide mechanical components with clear structural consistency, so understanding this construction is essential for selecting suitable solutions.

A heat pipe heatsink combines high-efficiency heat pipes with a metal base and fin structures to enhance thermal performance. Heat pipes rapidly transfer heat from the source to the fin area by using phase-change technology: the working fluid inside evaporates at the hot end, moves as vapor, condenses at the cooler end, and returns via capillary action. With the closed-loop cycle, heatsinks can achieve fast and efficient heat transport, while the extended fin area increases surface area for effective dissipation.

Material Choices That Support Thermal Transfer

When professionals evaluate a heat pipe heat sink, they focus on materials that support fast thermal movement and stable operation. Most solutions rely on copper pipes because copper offers high thermal conductivity and steady process performance. The fins of a heat pipe heatsink are typically made from aluminum, providing a balanced combination of conductivity and structural stability without unnecessary weight. They often choose different aluminum grades depending on stiffness requirements, airflow environments, and manufacturing preferences.

In many project discussions, engineers consider how these materials interact with each other rather than viewing them separately. For example, the bond between the copper pipe and aluminum base influences how quickly heat spreads before reaching the fins. Companies such as Dingmetal, which work with mechanical and thermal-related components, frequently support these engineering decisions by ensuring machining tolerances, material consistency, and uniform structural quality.

Structural Elements Shaping Performance

The internal and external structures of a heat pipe heat sink determine how smoothly the thermal cycle operates. Inside each tube of a heat pipe heatsink, a wick structure lines the wall, maintaining capillary action that keeps the working fluid moving through the loop. The geometry of this wick—whether sintered, grooved, or mesh-based—affects how well the pipe handles orientation and continuous heat loads.

Externally, fin spacing and base thickness influence airflow behavior and mechanical compatibility with surrounding assemblies. These structural considerations allow buyers, R&D engineers, and thermal designers to match the heatsink to the intended application. They usually look for stable production methods, and suppliers like Dingmetal often support these expectations by offering predictable delivery schedules, consistent machining, and process management to help customers align structural design with practical assembly needs.

Conclusion: Structural Understanding for Practical Thermal Applications

Gaining a clear view of how a heat pipe heat sink is built enables engineers to make informed choices when handling controlled temperature environments. Recognizing how materials combine inside a heat pipe heatsink, along with the structural elements that support heat transport, helps buyers and technical teams evaluate whether a design fits their project goals. Companies such as Dingmetal play a supporting role by providing mechanical parts and production capabilities that help maintain consistency in these assemblies. With this understanding, professionals can better assess construction details and select solutions that match real engineering and manufacturing requirements.