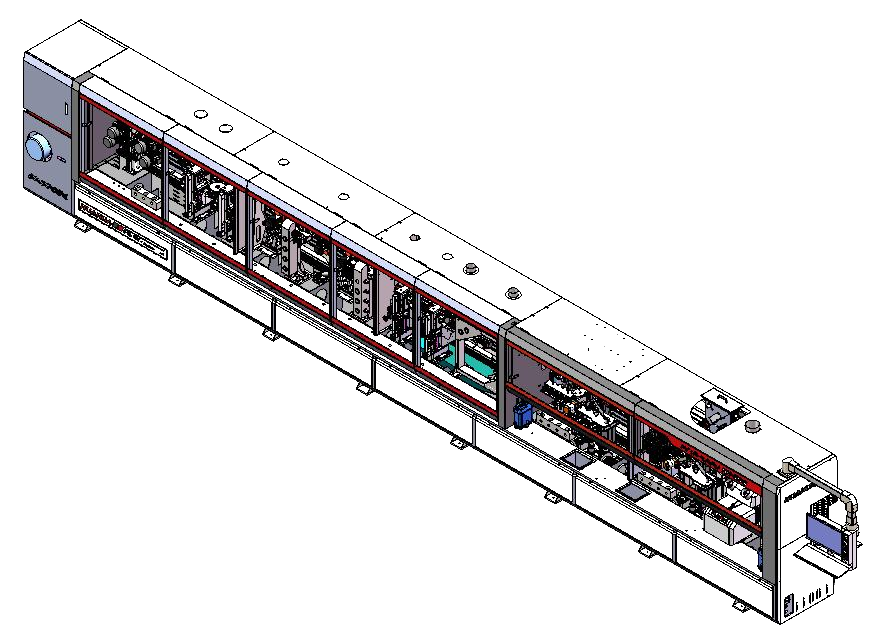

HUAHUA CNC has long been recognized as a leading manufacturer of advanced woodworking machinery. Among its innovative range of edge banders, the HH-796RK-SERVO stands out for delivering exceptional precision and efficiency. With advanced features like front releasing, heating lamps, and servo-controlled cutting, this machine ensures high-quality results while extending the durability of panels.

Front Releasing for Cleaner Processing

The HH-796RK-SERVO is equipped with a front releasing system. By spraying a releasing agent onto the panel surface, the machine effectively isolates the panel from unwanted debris. This prevents contamination during the processing stage, keeping the panel clean and ensuring a flawless finish.

Heating Lamp to Prevent Cracks

Another standout feature of this HUAHUA CNC edge bander is the integrated heating lamp. Before banding, the lamp preheats the panel edges, reducing the risk of cracks caused by sudden temperature differences. This not only improves the bonding strength but also enhances the final appearance of the panels.

High-Speed Horizontal End Cutting

For perfect trimming, the HH-796RK-SERVO utilizes a high-speed horizontal end cutting system. The band cutting saw blade is servo-adjusted, allowing precise angle modifications to suit different production needs. This flexibility ensures smoother, more accurate cuts that meet the highest standards of modern furniture manufacturing.

Conclusion

The HH-796RK-SERVO from HUAHUA CNC exemplifies how every detail in edge banders contributes to superior results. With its advanced releasing system, heating technology, and servo-controlled cutting, it provides manufacturers with a reliable, high-performance solution for panel processing. By choosing HUAHUA CNC, businesses can achieve greater efficiency, consistency, and quality in woodworking production.