Applying labels to pharmaceutical products at high velocity introduces a distinct set of challenges, particularly when using thin or fragile materials. The risk of tearing, wrinkling, or misapplication is significant without precise engineering. For a specialized labeling machine manufacturer like Pharmapack, designing a high speed labeling machine that mitigates these risks is a core aspect of their development process, ensuring integrity and accuracy are maintained even at maximum operational throughput.

Precision in Label Dispensing and Handling

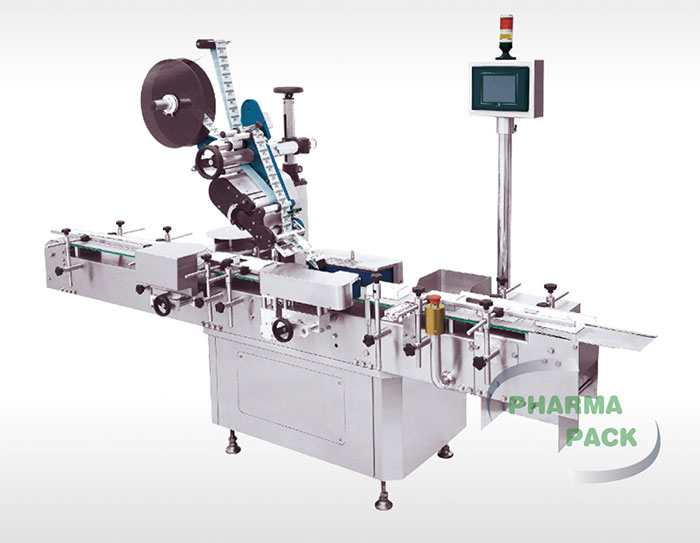

The primary factor in preventing damage is the exact control of the label dispenser mechanism. Pharmapack’s LFLB-4120 flat labeling machine addresses this with a servo motor-driven dispenser that employs closed-loop control. This system allows for label dispensing accuracy within 0.2mm, eliminating the jarring movements and imprecise stops that can cause stress and tears in delicate materials. By ensuring the label is presented and released with exact consistency, this high speed labeling machine manages the material gently, even when operating at speeds up to 60 meters per minute.

Adaptable Configuration for Varied Materials

A rigid system cannot accommodate the unique demands of different fragile labels. Pharmapack’s design as a labeling machine manufacturer incorporates a label dispenser with multidimensional and angle adjustment. This adaptability allows the machine to be finely tuned to the specific tension and release characteristics of various thin-gauge materials. By aligning the dispensing angle perfectly with the product’s surface, the high speed labeling machine ensures a smooth, controlled application that minimizes lateral forces that could lead to tearing during the high-speed transfer.

Intelligent Control for Consistent Operation

Managing complex labeling parameters reliably requires advanced processing. The LFLB-4120 utilizes a specialized MCU-based control system for higher accuracy. This system allows the high speed labeling machine to receive signals from upstream equipment, synchronizing its actions with the flow of products to avoid mis-timed applications that could crush or tear a label. Furthermore, the machine’s capacity to store approximately 50 parameter groups is critical. For facilities running multiple product SKUs with different fragile labels, this feature permits instant recall of perfect settings for each one, drastically reducing the need for manual adjustments that can compromise label integrity.

In summary, handling fragile labels at high speed is a matter of precision engineering and intelligent control. It requires a labeling machine manufacturer with a focus on motion accuracy, mechanical adaptability, and operational consistency. Pharmapack’s technical specifications for their high speed labeling machine demonstrate a methodical approach to these challenges, providing systems that apply delicate labels effectively within the demanding environment of a pharmaceutical packaging line.