Reverse engineering a 3D model is a methodical and often difficult technical process that turns the physical shape of an object, which is captured by a high-resolution scanner, into a CAD (Computer-Aided Design) file that can be edited and made. To go from a physical object to a digital blueprint, you need special 3D reverse engineering software like QUICKSURFACE, which is part of the 3DeVOK professional ecosystem. The software is specially designed to turn raw, static mesh data into live, mathematical CAD features. This smooth workflow is very important for many industries when it comes to coming up with new ideas, making replacement parts, and analyzing designs. Scan-to-CAD is the name of the whole process, which has four main steps that all depend on the advanced features of the chosen software solution.

Getting Data and Making the Mesh

The workflow begins with data capture using high-precision 3D scanners like those from 3DeVOK, generating dense point clouds that are converted into standard formats (STL, OBJ, PLY). These meshes form the foundational digital representation of the physical object.

The subsequent mesh preparation phase addresses inherent scan imperfections through specialized 3D scanning reverse engineering software. This critical stage involves removing outliers, filling holes to achieve watertight geometry, and applying smart smoothing to reduce noise while preserving features. For multi-scan projects, the software precisely aligns all segments into a unified model. This meticulous preparation establishes the geometric integrity essential for all subsequent reconstruction steps.

Finding features and figuring out the design intent

This is where the real digital translation happens. The 3D scanning software reverse engineering platform takes the rough, static mesh and turns it into the exact, mathematical design intent that the engineers had in mind when they made it. This is made possible by the Geometric Primitive Extraction function. The engineer uses the software to choose specific areas on the mesh that represent basic geometric shapes, like perfect planes, true cylinders, ideal cones, or spheres. The software then uses advanced fitting algorithms to find and create the best mathematical primitive that fits the chosen points. This makes up for any flaws, wear, or noise in the raw scan data. This step is very important for getting the engineer’s design back on track.

As soon as these primitives are taken out, they are used to align the entire model with objects. The software accurately aligns the entire mesh to the world coordinate system, which is defined by the X, Y, and Z axes, by using three geometric features that are all perpendicular to each other. For example, the bottom face and two key side faces of a mechanical part. This alignment is very important for setting up the right manufacturing datum features and making sure that the final CAD model is in the right position and has the right orientation for CNC manufacturing, quality control, or assembly in a bigger digital context. The final model is so useful for engineering because the 3D reverse engineering software can apply these mathematical truths to the imperfect physical world.

Hybrid Modeling for Model Reconstruction

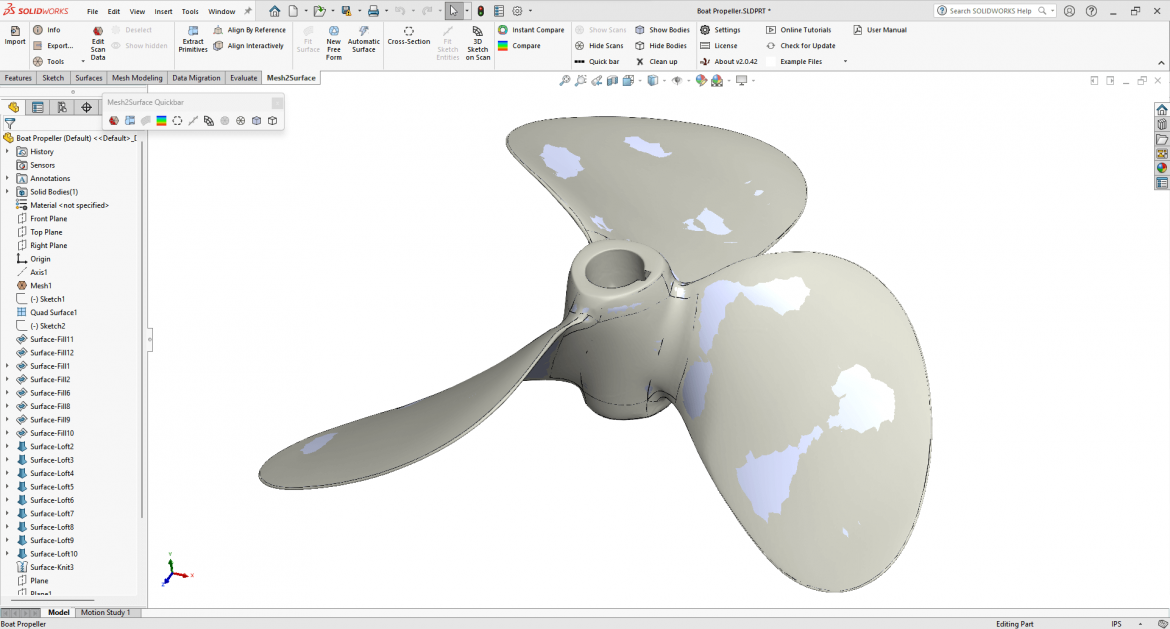

The prepared mesh serves as a high-accuracy reference for CAD reconstruction through a hybrid modeling approach. For technical components, the 3D reverse engineering software enables 2D sketching directly on mesh cross-sections. Engineers create dimension-driven sketches for mechanical features like mounting holes and structural elements, which are then transformed into parametric 3D geometry through extrusion and rotation operations.

For organic forms such as ergonomic grips or automotive panels, specialized surfacing tools generate NURBS surfaces that mathematically conform to the scanned contours. Advanced systems accelerate this process through automatic patch generation while maintaining manual control over curve tension and surface continuity. This dual capability ensures the reconstruction preserves both dimensional precision for mechanical parts and aesthetic quality for sculpted surfaces, delivering production-ready B-rep models.

Final Export and Validation

The final phase focuses on quality verification and data delivery to ensure the reconstructed model meets application requirements. A crucial component of this stage is the Real-Time Deviation Analyzer, a standard feature in professional 3D reverse engineering software. This tool generates immediate color-coded visualizations that precisely quantify the dimensional differences between the newly created CAD surfaces and the original scan data. This continuous metrological verification enables engineers to monitor reconstruction accuracy throughout the process, guaranteeing compliance with all specified quality and tolerance standards.

Following successful validation, the completed CAD model is prepared for export. Professional platforms ensure maximum compatibility through support for universal formats, including STEP and IGES. This export capability enables seamless transfer of high-precision data from 3DeVOK scanners to major manufacturing, analysis, and simulation platforms worldwide. The final deliverable is a fully parametric, production-ready digital asset that effectively bridges physical objects with practical engineering applications.